Customer Overview

A stacker crane cold storage project for a frozen food company, compatible with multi-story workshops and facilitating information integration.

The first phase's inventory is sufficient to support current production capacity, and a new warehouse is needed to increase inventory.

Phase II will launch and replace the first phase's software system.

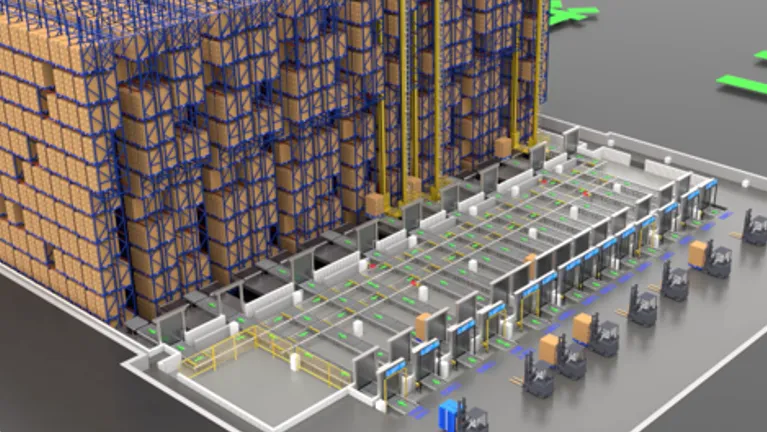

Six stacker cranes and numerous conveyor lines connect the warehouse and production workshop. Designed to accommodate 11,736 cargo bays, the project meets the required 180 pallets/hour of total efficiency.

An intelligent warehouse management system is implemented to improve warehouse management and informationization.

Also, considering the customer's production continuity, the project provides emergency response capabilities.

Long logistics routes, with workshops located on both sides of the warehouse, hinder connectivity.

The warehouse is newly built and needs to be a benchmark factory in Shandong Province.

Manual labor efficiency is low

Achieving unmanned and intelligent warehouse operations.

Significantly improve warehouse efficiency by separating outbound and inbound storage.

Optimize traffic flow by strategically arranging multiple buffer rooms within the limited hallway area.