A major domestic power grid company responsible for power transmission and distribution network operation and maintenance across several provinces. With annual material procurement exceeding 1 billion yuan and a catalog of over 10,000 types of power equipment and spare parts (e.g., transformers, cables, insulators), it urgently needed to build an efficient and intelligent warehousing and logistics system to support the safe and stable operation of the power grid.

The traditional warehousing model faced three major challenges: low space utilization (only 35%) due to the diverse sizes of power materials (from precision instruments to large equipment); slow response times for emergency repair materials (averaging over 6 hours), impacting fault recovery speed; and high inventory discrepancies and difficult traceability due to manual record-keeping. An intelligent upgrade via a four-way shuttle-based AS/RS was urgently required.

High-Density Storage: A combination of four-way shuttles and heavy-duty racks, with customized locations for different material sizes, created 20,000 storage units. Space utilization increased to 82%, expanding capacity by 134% compared to traditional warehouses.

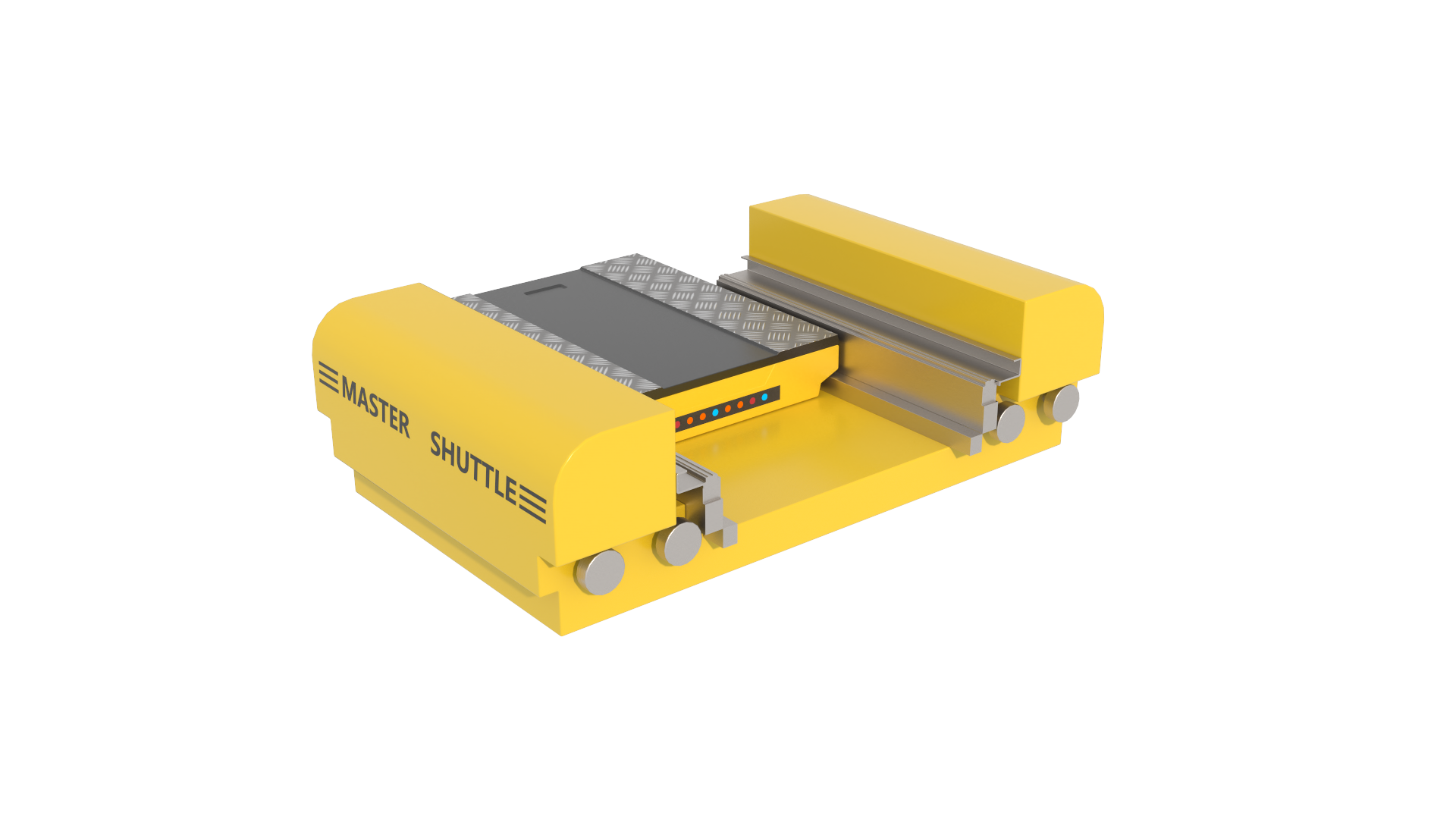

Full Automation: 25 four-way shuttles, 8 heavy-load elevators, and intelligent conveyors enabled automatic storage, retrieval, sorting, and inventory of power equipment, achieving a throughput of 1,000 pallets/hour.

Smart WMS Integration: A Warehouse Management System integrated with ERP enabled demand forecasting, automatic replenishment, batch tracking, and full lifecycle management. Linkage with the grid dispatch system ensured rapid response for emergency repair materials.

Heavy and Precision Compatibility: The system needed to handle both heavy transformers (over 5 tons) and precision instruments, requiring strict standards for rack load-bearing and shuttle stability.

Complex Environment Adaptation: Some power equipment required constant temperature and humidity storage, demanding shuttle operation reliability under specific environmental conditions.

Deep System Integration: Seamless 对接 with the grid's existing ERP and dispatch systems was necessary to achieve real-time data synchronization and closed-loop business processes, presenting significant integration challenges.

Efficiency Improvement: Emergency repair material response time was reduced to under 1 hour, improving fault recovery efficiency by 6x and strongly supporting grid safety.

Cost Optimization: Labor costs were reduced by 70%, space utilization increased by 134%, resulting in annual warehousing cost savings exceeding 5 million yuan.

Management Upgrade: Full lifecycle digital management of materials was achieved, with inventory discrepancy rates below 0.1%, providing data support for lean grid operation.